Today we have part one of a two part reflection on the Terroir of Calvados – the place, the producers, and the many details that make the apple spirits produced in a small region of Normandy unique. At Ambix Spirits we are seeking the terroir of Sonoma County. However, to understand our own terroir, we need to first understand that of our old world inspiration, Calvados. We were able to take a short late winter trip recently to visit Calvados to visit distilleries, to talk to producers, and to learn their techniques.

Below are some stories and discoveries from that trip about place, the orchards, and fermentation. In our next newsletter we will then continue with reflections on distillation and maturation of the spirits.

The Place

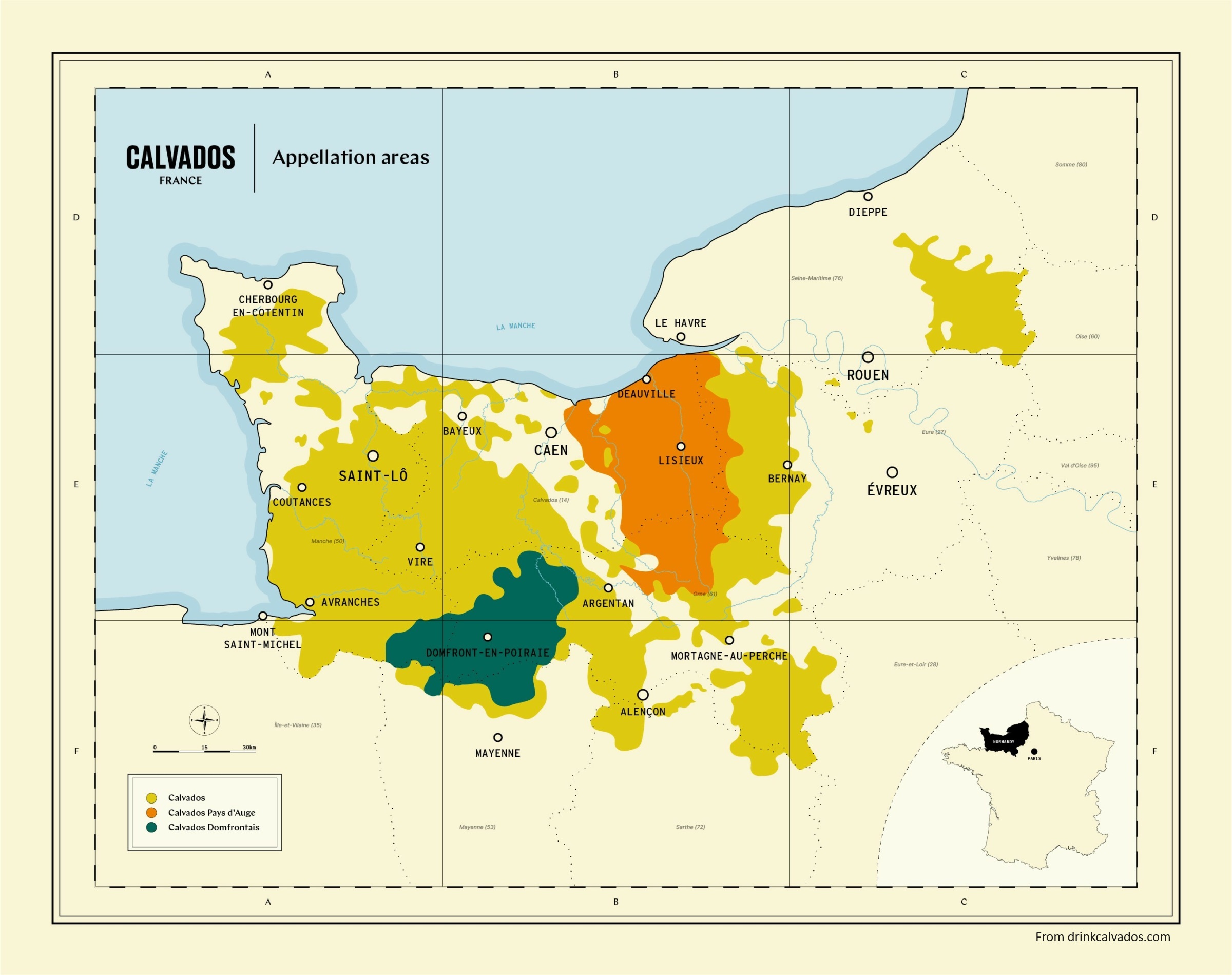

Calvados AOC is a protected appellation in Normandy that is loosely centered on the Calvados administrative region of France. The AOC is defined by the terrain of river valleys, soils, and tradition

The AOC of Calvados has two sub-appellations: Pays d’Auge and Domfontais. Pays d’Auge (orange in the above map) is a north south river valley centered on Lissieux. In this AOC, distilling is done in an alembic pot still (double distillation) with heavy use of tannic apples. Domfrontais (green in the map) is in the south of Calvados and is known for its use of pears (> 30% required) and continuous column distillation. Outside of these two sub-appellations the apples and distillation techniques vary widely. At Ambix Spirits our techniques and approach is most closely tied to that of Pays d’Auge.

The Apples & Pears

As you enter the orchards of Cavados, the Haute Tige (High Stem) orchard training is the first striking evidence of the terroir of Calvados. This unique Norman style of training removes all branches below ~6’ and results in exceptionally tall tree with all the branches and fruit being well above your head. These large trees are also much more widely spaced than in a modern orchard. There is a good reason for this! Many orchards double as pasturelands for the famous Normande breed of dairy cows. This allows for two sources of income from the same land. Most Calvados producers do not make their own cheese commercially instead selling to a co-op. We had plenty of Norman Camembert, Neufchâtel, Pont L’Évêque, and Livarot to sustain us in our journeys.

Nearly every orchard we visited was certified organic, did not spray, dry farmed, and performed minimal active orchard management other than pruning. The cows don’t just produce milk, they also are responsible for the mowing, weeding and fertilization of the orchards Everything comes with a tradeoff and with widely spaced, tall dry farmed apple trees fruit yield is low and varies greatly from year to year (2-5 tons per acre), far less than what is produced in modern orchards which produce over 10 tons per acre. Also important to the terroir of Calvados, the nitrogen and other nutrient content of the apples is low which results in slow and challenging fermentations.

Hand picking apples from tall trees is impractical, so they are allowed to fall to the soft grassy floor and are swept up by mechanical harvesters every few days. Many producers help the harvest along by shaking the trees, but some we spoke with took pride in waiting for the most mature apples to fall naturally and never shaking their trees to speed the harvest.

Juicing & Fermentation

Orchards in Calvados have tens of different types of apples but all of the apples are all combined together during juicing operations. No producer that we spoke to was trying to make specific blends with a subset of apples to drive specific flavor profiles. A few producers did speak of ‘early’ vs ‘late’ apples and different uses for them, but in most case everything that was picked went into a master juice blend that would then be used for both cider and calvados production

Surprisingly there was little to no ‘sweating’ (a post harvest storage period used to further mature the fruit, a common practice in other traditional cider regions) performed at the producers we visited. Apples were juiced once or twice a week as soon as enough were available.

Juicing was typically performed by grinding the apples to a pulp into a large hopper. The pulp mash to sit for a few hours to break down & oxidize often with some agitation before it was pumped into the press. We mostly saw bladder presses being used for juicing. While bladder pressers are commonly used for wine in California, very few domestic cideries use them for cider. Instead most California producers use either traditional rack and cloth presses or modern belt presses. Other than an ancient press in a cellar, we saw no one using the rack and cloth presses in Calvados, but a few were using the more modern belt press.

Upon reflection, of all the steps of Calvados production, less attention was placed on the blending and juicing techniques. It is intriguing that with so much focus on apple tree size and shape, on fermentation and maturation, that the actual juicing was less of a focus. We would like to explore this topic on future trips at other producers.

In comparison, the fermentation technique is one of the most critical components of the terroir to the producers of Calvados. Native yeasts were used at all producers we visited, and no nutrients are added to the juice. Normandy is not known for great weather and is typically well below 50 F when the ferments occur. The combination of natural yeast, cold temperatures, and nutrient deficiency results in a slow primary fermentation that typically takes over 4 months to complete, maybe 10x slower than any cider production seen in California. Most producers used low cost fiberglass fermenters for this step and would distill in the spring as soon as the fermentation finished. Some others would age their cider even longer. For example at Manoir de Montreuil Patrice Giard (seen above), a 13th generation cider maker ages his cider for a full year in a giant (~10,000 gal) tonneau that dates back to 1904. It should be noted that very little effort is made to keep these ferments clean, and there is plenty of volatile acidity and funk that develops over this lengthy ferment.

Many aspects of the terroir of Calvados are clearly unique and inseparable from the region: the dual-use orchards, the minimal intervention approach, the long funky fermentation, and the strong impact of the cold and rainy weather on all aspects of production. Our challenge now is to figure out what techniques can and should be adapted to the terroir of Sonoma County, and what we need to respect as inseparable from the place, and thus simply needs be different in Sonoma County. These differences get even more unique and surprising as we get into distillation and maturation in Part 2 next time. We’ll leave you with this cliff hanger for now. See you next time.. same Ambix Time.. same Ambix Channel!